About us

Mayra CIA SAS is located in Colombia more specifically La Estrella, Antioquia; few minutes away from Medellín. Our privilege position allow us shipping from the Atlantic and pacific ocean to our customers abroad. Founded in 1983 starting with plastics injections and now with vulcanization and rubber extrusion.

Designing and manufacturing products according to drawings, samples or customer needs; working with high quality standards in accordance with the technical requirements of each product. Our laboratory is equipped with tools and instruments to guarantee and meet the dimensional, resistance and useful life specifications, that’s why our clients trust us.

Mision

Mayra & Cia is a company dedicated to the manufacture of industrial articles in rubber and plastics, supported by competent human talent and technological development to satisfy customer needs.

Vision

Mayra & Cia by 2022 will be an international recognized company for it’s quality in the rubber and plastic industry.

Quality

Mayra & Cia Aware of the needs of the national industry has developed high quality products to avoid damage and production losses caused by defective or short-lived parts, for these purposes we have qualified personnel, state-of-the-art machinery and standardized processes that make us competent nationally and internationally.

How do we do it?

Analyzing

Preparing

Working hard

Completing

Testing

Delivering

Environment protection

Our commitment to the environment is to maintain a balance of natural resources, implementing conservation and protection activities, promoting the proper management of waste derived from rubber and plastic, which are properly treated, avoiding causing negative environmental impacts, ensuring the conservation of a clean and healthy space for our community in general.

Human talent

The human talent of our company is characterized by its good sense of belonging, motivation and active participation in the optimization of processes and products. There is constant training and updating to maintain excellent quality, finishes and long life of all manufactured items.

Corporate social responsability

The human talent of our company is characterized by its good sense of belonging, motivation and active participation in the optimization of processes and products. There is constant training and updating to maintain excellent quality, finishes and long life of all manufactured items.

Our products

-

-

M1573 RUBBER LEVER XCD

-

M1573 B RUBBER LEVER XCD

-

DISINFECTION MAT

60 x 80 -

SEAT SHOCK ABSORBER

-

M1528 RUBBER STOPER PULSAR 200

-

M1665 BIG SUPPORT

-

M1444 WASHER 11X19X5

-

M1666 SMALL SUPPORT

-

M1236 GAS TANK CAP

-

M1913 SMALL RECTANGULAR SADDLE SHOCK ABSORBER

-

M1914 SMALL RECTANGULAR SADDLE SHOCK ABSORBER

-

M1911 RUBBER WALLET PULSAR

-

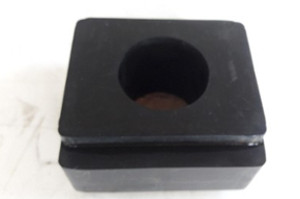

M1442 SQUARE PLATINUM RUBBER

-

FLAP O COLEPATO

-

M1564 RUBBER FENDER CAP XB 24

-

CONES SLIDER

-

M1797 RUBBER STOP-SL-NKD

-

HANDLE CAP - HANDLE

-

-

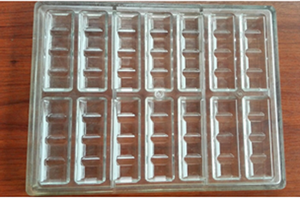

POLYCARBONATE TRAY

-

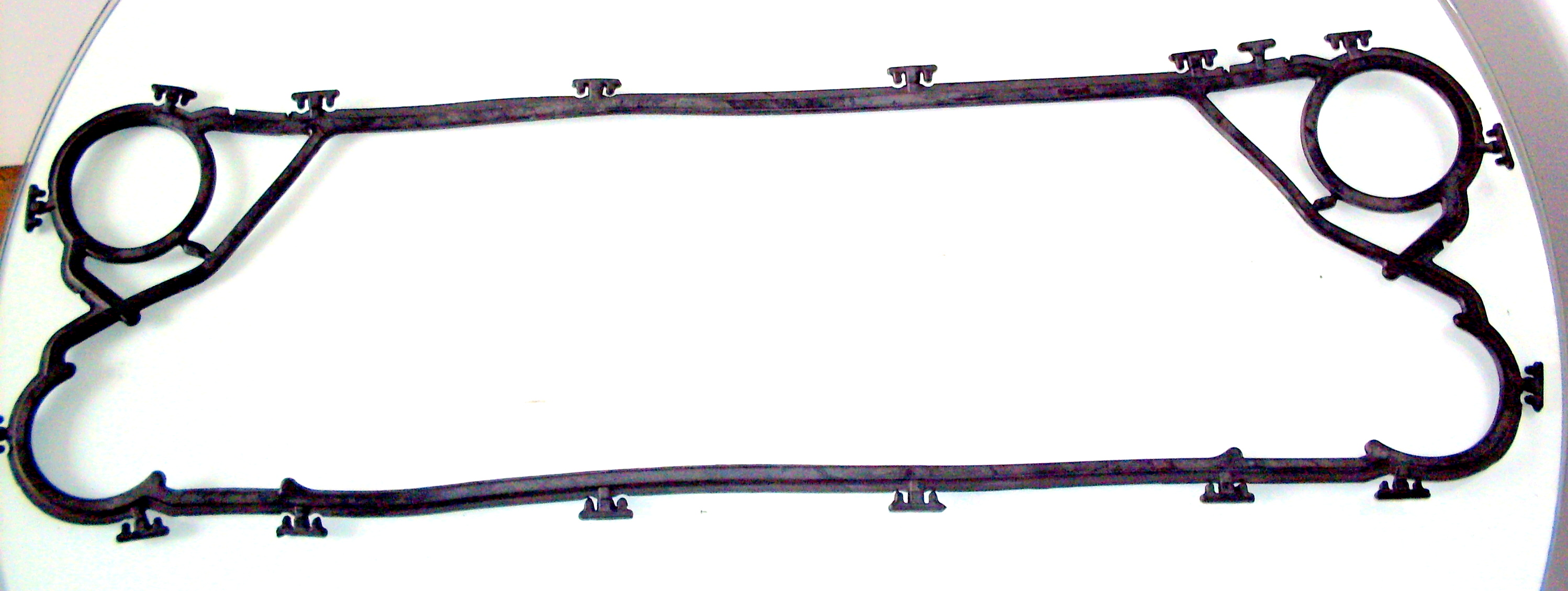

EXCHANGER

-

-

-

-

FUELLE

-

ROLLER TOWSEND

-

FOOD POWDER CONVEYOR SYSTEM

-

-

Spare parts for bottlers

-

Spare parts for bottlers

-

Spare parts for bottlers

-

-

WALL SEPARATOR 7 CMS

-

WALL SEPARATOR 2.5 CMS - 3CMS

-

M1997 53/4" CENTRALIZER SEPARATOR"

-

M0506 YUMBO ROD CENTRAL SUPPORT

-

M1313 WINCH PLATE

-

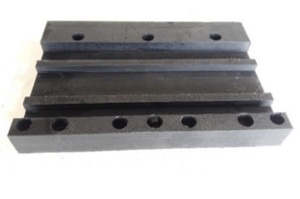

GUIDES FOR SLIDES

-

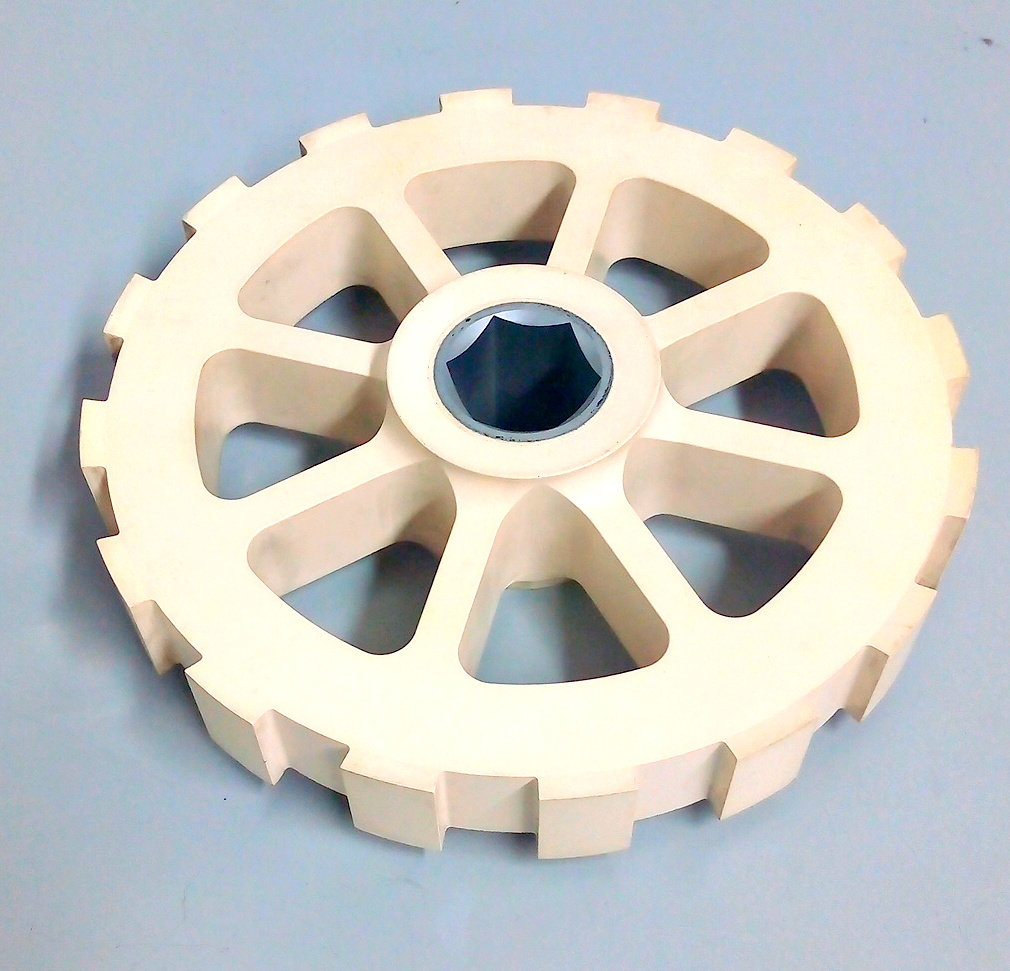

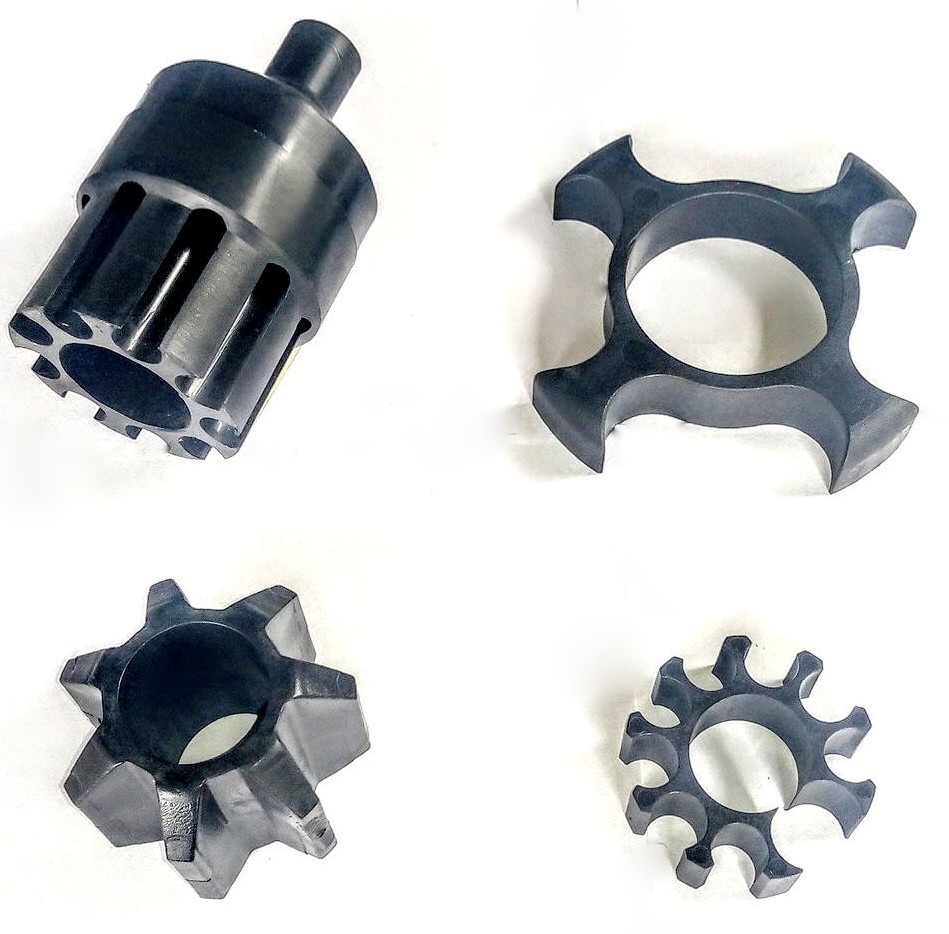

M0170 PIÑÓN TABLE TOP

-

M1739 PACKING FILTER PRESSES

-

M1180 PACKING FILTER PRESSES

-

M0287 CONCRETE PIPE

-

M1132 BUJE BALANCIN TRAYLER UTILITY

-

CENTRALIZING SUPPORT FOR YUMBO DRILL

-

TRACTOR WHEEL

-

M493 M1453 SPHERES

-

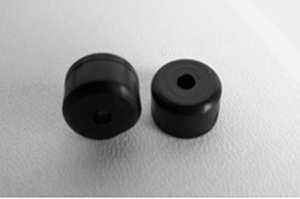

ANTI-VIBRATION MOUNTS

-

-

M0053 ALIVA DISC

-

M539 DUMP TRUCK SUPPORT

-

M1407 BEARING SUPPORT

-

CONCRETE SHUTTLE PACKAGING

-

RUBBER BOP

-

SHOE FOR ASPHALT PAVER

-

HOSE GUIDE CART

-

CONCRETE PUMP PACKING

-

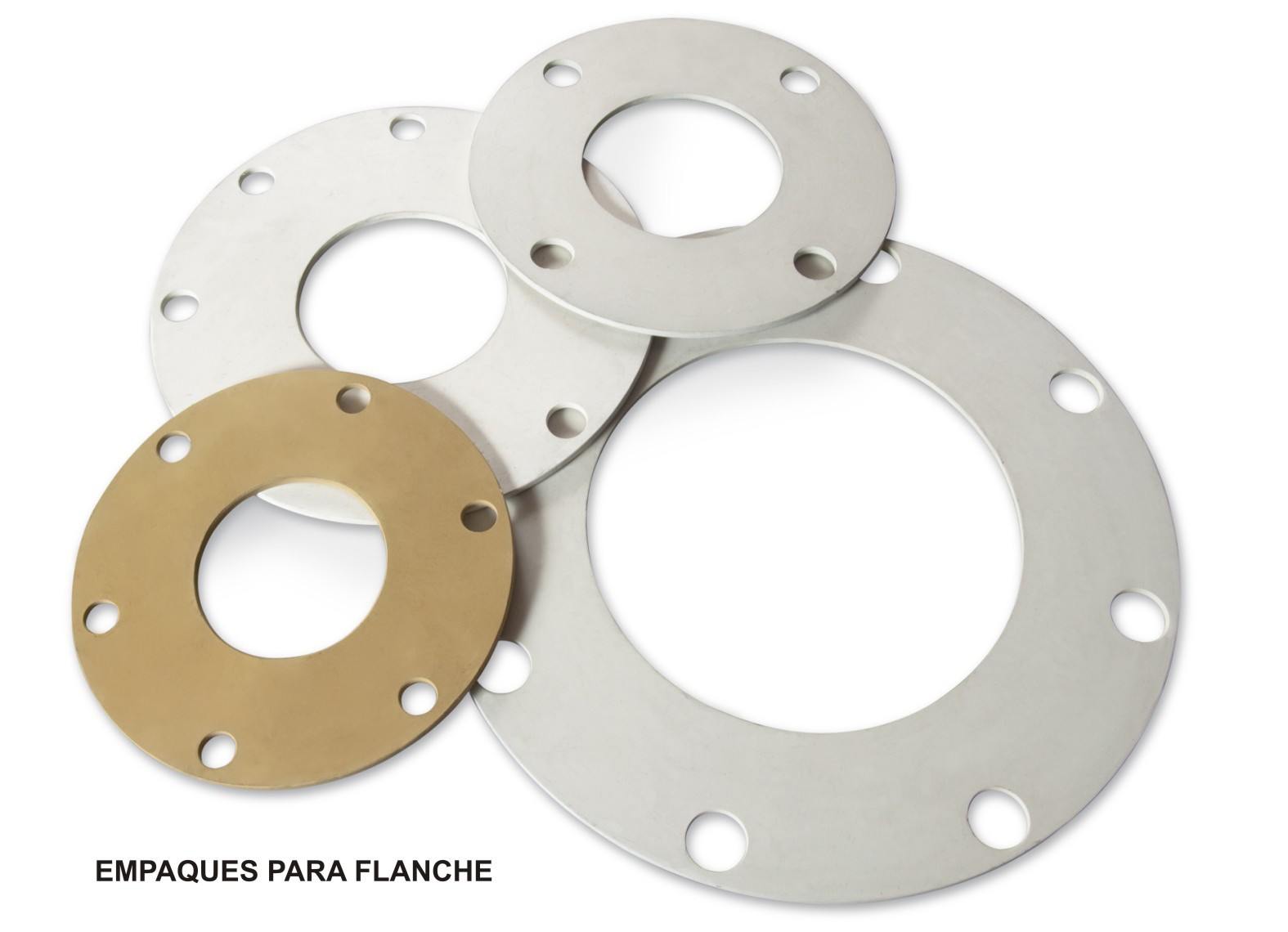

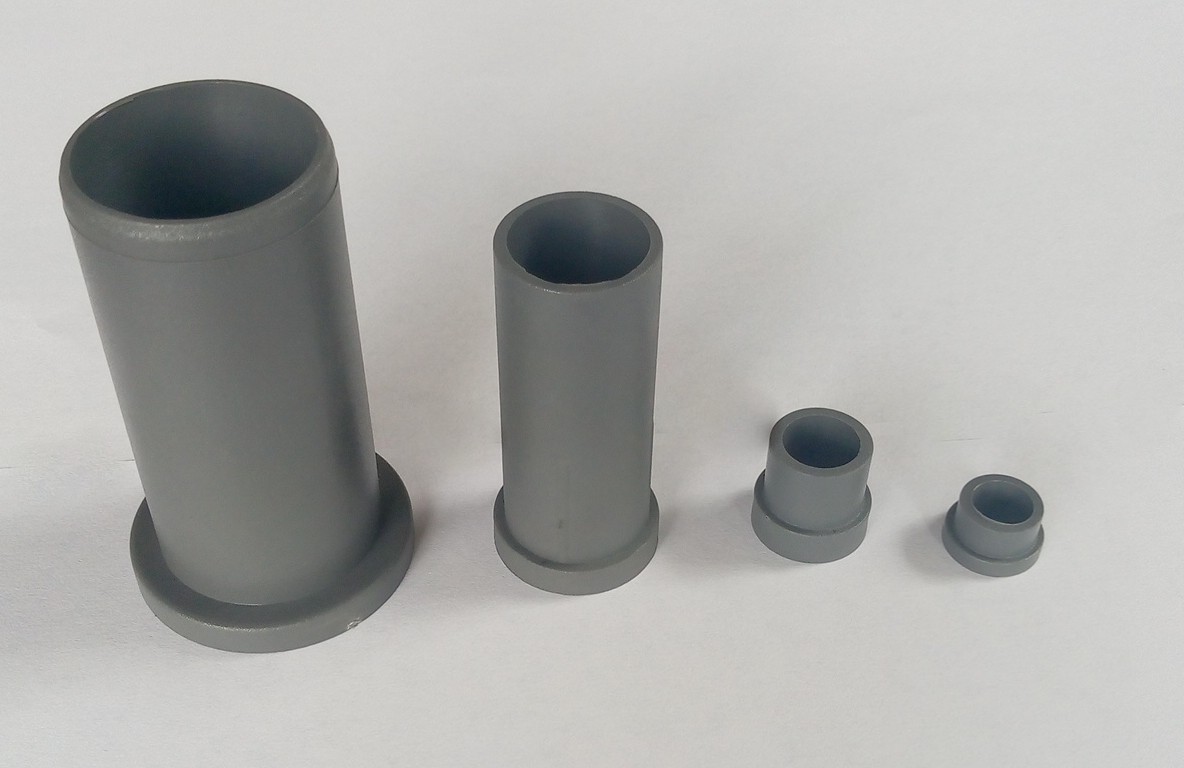

FLANGE, SIPHON

-

BASE COVER 8

-

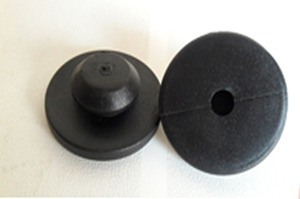

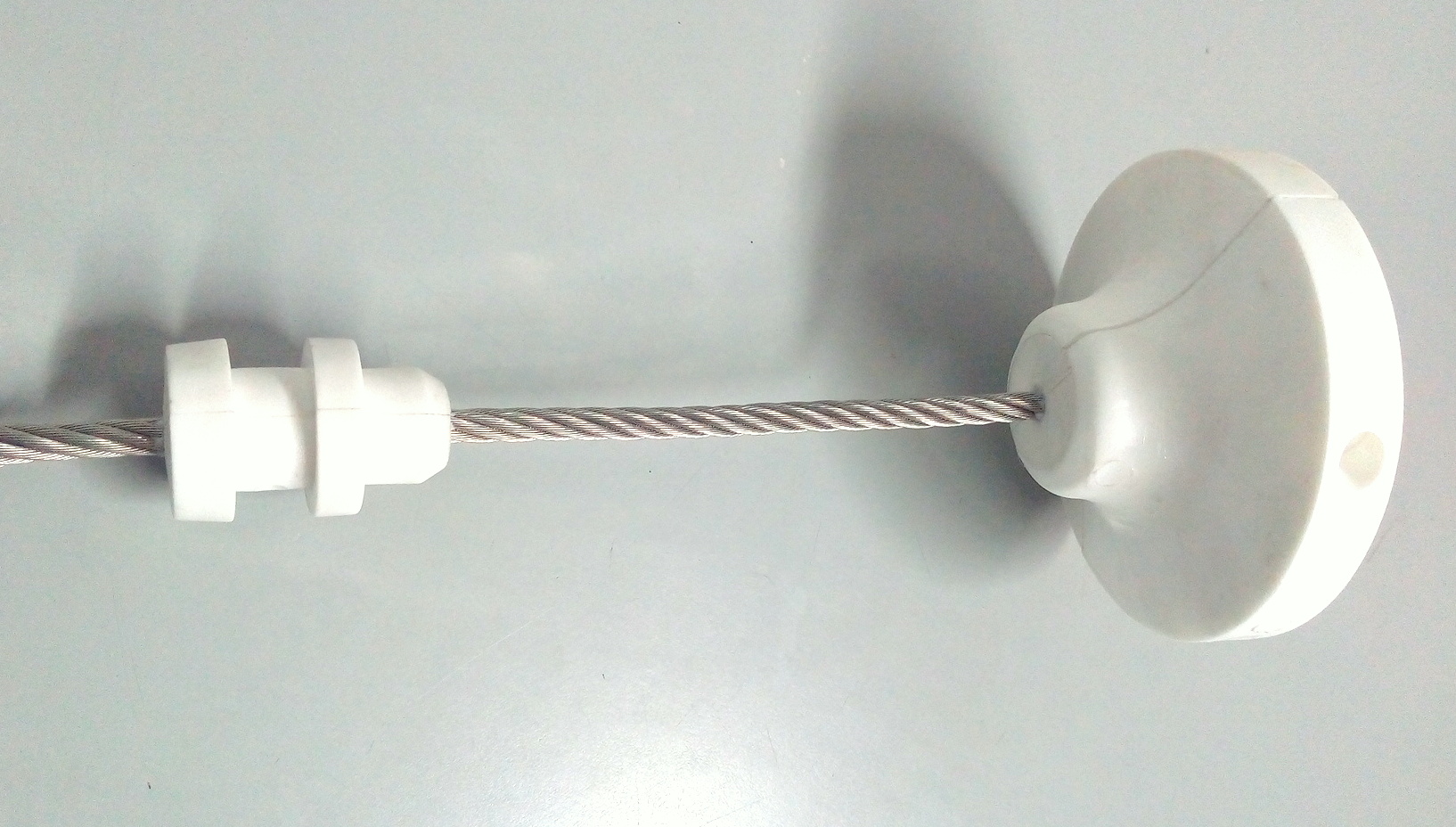

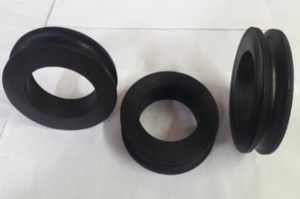

Cable grommets

-

Cable grommets

-

-

DUST GAITER

-

-

-

-

-

-

-

-

-

-

-

Do you like our products?

The following services are provided

Plastic Injection Molding, Plastic Injection and Rubber Vulcanizing Services.

Roller Retrapping

Mold Manufacturing Service for rubber and plastic articles.

Our clients

We have modern plastic injectors with capacities between 40 grams and 500 grams, where we work with different types of materials such as polypropylene, polyethylene, flexible PVC, engineering plastics such as Nylon, Polyacetal and ABS.

Contact us

Location

CR 55 # 79 Sur 68La Estrella - Antioquia

Phone

+ 57(604) 322 80 92+ 57(304) 665 61 52

+57 312 8400541